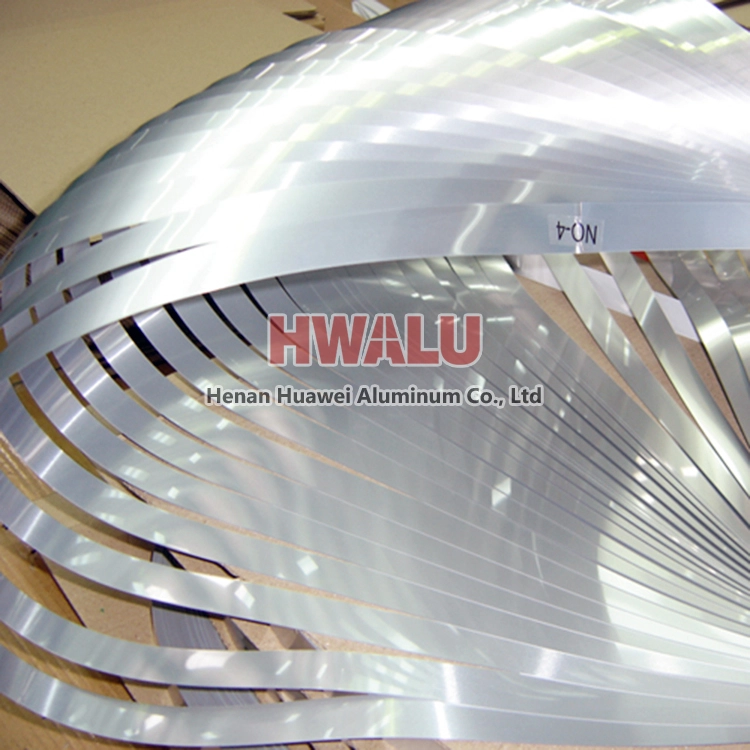

Aluminum Strip

Aluminum strip ( aluminium band ) the first is the production of raw materials, no matter the raw material is processed, and the raw material of the aluminium coil strip is aluminum ingot. The aluminum ingot is usually melted into aluminum water, and then the liquid aluminum water is put into the continuous casting machine, and the aluminum water is rolled through the casting mill. Usually the thickness of casting roll is between 8-10mm, which is the first step in the production of aluminium coil strip.

The precision rolling process is then made by the finishing mill. The precision of the mill is usually controlled within 0.01mm. Of course, the finishing mill is a new rolling mill instead of the old type of equipment eliminated in 90s. The finishing mill rolling the rolled roll over and over again to the required thickness, which is second of the aluminium strip production. The Ministry step is also the most important step.

Then we need to cut and clean the rolling material after rolling, cutting edge is cut off the uneven edge after rolling, and cleaning is because the finishing mill is rolled in the rolling oil, so the surface oil pollution must be cleaned.

Finally, annealing, winding and packaging, annealing is in the constant temperature of the annealing furnace for a period of time, through the high temperature change the internal grain size of the aluminium coil strip to obtain a variety of mechanical properties and elongation, and then after annealing, the need to reel through the winding equipment, after processing for various kinds of aluminium strip packaging.

News

The first is the production of raw materials. Regardless of whether the raw materials are processed, the raw materials of aluminum coils are aluminum ingots. The aluminum ingot is usually melted into molten aluminum, and then the liquid aluminum water is put into the continuous casting machine, and the molten aluminum is rolled through the casting and rolling machine. Usually the thickness of the casting roll is ...

Aluminium strip casting is a key factor in weight reduction, especially in the automotive industry, and despite being developed for over 50 years, strip casting is still gaining popularity. Casting speed can be limited by several factors, including the type of alloy cast and the desired plate thickness required. In the automotive industry, weight reduction is one of the most important challenges to solve, and ...

Whether it's architectural appearance or interior decoration, the use of aluminum strip is reflected in all aspects of life. The raw material of aluminum strip (aluminum strip / aluminum strip) is pure aluminum or aluminum alloy roll casting and hot rolling aluminum coil, which is rolled into thin aluminum coil of different thickness and width by cold rolling mill, and then cut into aluminum strips of different w ...

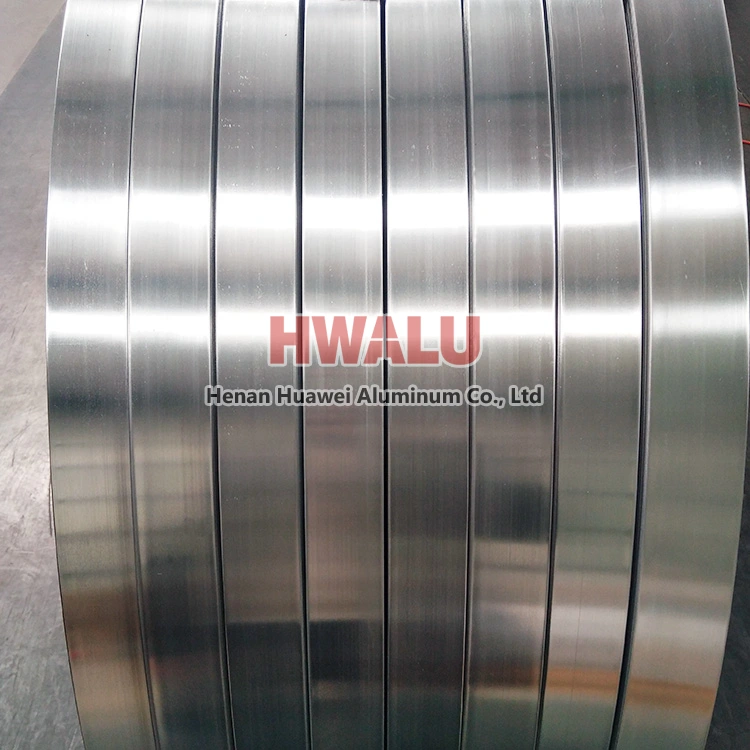

Transformer aluminum strip is the key raw material for manufacturing of transformer windings, it is rolled by the aluminum ingot. Transformer aluminum strip can be divided into different alloy, specifications, temper according to the usage . The alloys include: 1060,1050,1050A, 1060,1070,1070A, 1350, temper: O,temper O stand for soft state, followed number show the degree of hard and soft, and the level of annea ...

With the rapid development of China's economy, the rapid growth of electricity consumption, urban and rural power grid reconstruction and expansion efforts to further increase the amount of dry-type transformers also increased rapidly. In the past, the Aluminium strip aluminum foil used in dry-type transformers all depended on import, and affected the development of dry type transformer manufacturing in China in ...

Henan Huawei Aluminum Co., Ltd is good at aluminum plate/aluminum strips processing for many years, transformer aluminum strip because the industry requirements are relatively high, so in the production and processing at the same time, must be strictly checked, in order to ensure that each batch of goods are exquisite. Transformer aluminum strip is done after machine slitting from aluminum mother coil, so need t ...